3D printer

Choosing

- FlyingBear Ghost 4S – €271, BMG Extruder, STM x32 control board, Print size: 255×210×210mm, Positioning accuracy: Z 0.002 mm, XY 0.01 mm, Nozzle diameter: 0.4mm, Max printing speed: 150 mm/s, Control software: Repetier-host, Cura; Supported materials: TPU,PLA,ABS,WOOD,HIPS

- Anycubic I3 Mega – € 174

- Tevo Nereus – 320×320×400, MKS Robin Nano control board, Print size: 210×210×205mm, Max printing speed: 150 mm/s, Nozzle diameter: 0.4mm (type MK8), XYZ Positioning accuracy: 0.05 / 0.05 / 0.1 mm, Supported materials: PLA, ABS, Wood, PVA, HIPS

- Tevo Tarantula Pro: Print size: 235×235×250mm, Metal E3D Bowden extruder, Max printing speed: 150 mm/s, Nozzle diameter: 0.4mm, XYZ Positioning accuracy: 0.012 / 0.012 / 0.004 mm, Supported materials: PLA, PETG, Wood, PVA

- FLSUN QQ-S-Pro – €304, Print size: 255×360mm

- Artillery Sidewinder X1: €415, MKSGen L control board, Print size: 300×300×400mm, Max printing speed: 150 mm/s, Titan Extruder, XYZ Positioning accuracy: 0.05 / 0.05 / 0.1 mm, Supported materials: PLA, ABS, TPU

- Two Trees Sapphire S: Print size: 200×200×200mm, STM 32F407VET6 control board, double nozzle fan, Max printing speed: 180 mm/s, XYZ Positioning accuracy: 0.01 / 0.01 / 0.1 mm, Supported materials: PLA, ABS, Wood

- Обзор 3D Printer CREASEE CS 30, настройка механики, final upgrade 3D Printer CREASEE CS 30 – лучший бюджетный принтер из Китая 300×300×400.

- Обзор Elegoo Neptune 4 Pro высокоскоростной FDM 3D принтер нового поколения, Neptune 4 ($229) – 225×225×265, 250-500 mm/s, Killper

Tuning

Mechanics and design improvements

Mechanics

Input shaping / vibration compensation:

- Input shaping without changing firmware by means of special stepper motor drivers by GH SmartShaper (~€40). Software support is already in Klipper and will appear in Marlin v2.1.x.

Motherboard

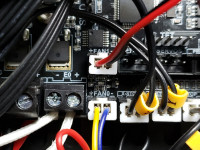

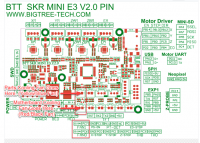

- SKR Mini E3 V2.0 - Complete guide to the best value Ender 3 upgrade – features 32 bit ARM Cortex-M3 processor STM32F103RCT6 and the latest TMC2209 drivers

- Обзор 32-х битной платы - SKR mini E3 V2.0 (read description)

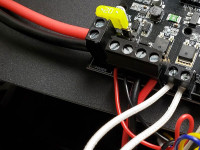

- Alternative wiring with hotend fan on FAN1 and part fan on FAN0 – requires

E0_AUTO_FAN_PIN FAN1_PINsetting inConfiguration_adv.h.  Better alternative is BIGTREETECH E3 RRF V1.1 (STM32F407VGT6 168MHz, 4×TMC2209, ESP8266) – $38.68+$1.46 (manual) which supports ESP3D with Marlin or DWC with RepRapFirmware (directly updateable from SD card)

Better alternative is BIGTREETECH E3 RRF V1.1 (STM32F407VGT6 168MHz, 4×TMC2209, ESP8266) – $38.68+$1.46 (manual) which supports ESP3D with Marlin or DWC with RepRapFirmware (directly updateable from SD card)

- Настройка BLtouch на Creality Ender-3 с платой SKR E3

Auto bed leveling mesh visualizerUse this script to disable end stops so that one can move to negative Z offsets from menu. Check G29 - Automatic Bed Leveling for more information and LCD Menu: Bed Leveling concerning what G-code commands are executed.

Extruder

- Гайд по доработке Ender-3/CR-10/Aquila – установка direct extruder, замена платы управления, доработка охлаждения

- Extruder mods:

- Улучшение обдува радиатора – лучше распечатать custom cooling fan ductinator

- CR-10 / Ender 3 direct drivinator – adapter for Ender-3 extruder that turns it into a direct extruder.

- Extruder upgrade:

- Тест термобарьеров. Что купить? Стальной, титановый или биметаллический?, Bi-metallic heat breaks - a revolution?! – due to the multi-material construction helps to avoid heatcreep (when filament trend to get soft way before heating zone and eventually blocks the filament path) by using a stainless steel (has lower thermal conductivity) instead of copper for a throat which allows to increase the melting rate and therefore decrease the backpressure for extruder motor helping with extruder skips (so go faster / thicker / wider).

- Термоблоки хотенда 3D принтера – сравнение, тест латуневого и алюминевого термоблока. Латуневый почти не реагирует на паразитный обдув хотенда и может быть использован без силиконового носка. Алюминевый быстрее остывает.

- Video review NF Smart CR10 Hotend for Ender 3 or CoreXY, Сравнение хотэндов MK-8 и NF Smart CR-10 Hotend – замена стокового радиатора CR10 на термобарьер+радиатор в одном (€31.47).

- Bondtech CHT nozzle is 30% more performant than Volcano.

- Высокопроизводительное сопло CHT. Вулкан больше не нужен? – опровергает производительность CHT в пользу Volcano.

Double Z-axis

Other

Spare parts

Before printing

Firmware

- ESP3D is a firmware for ESP8266/ESP32 with web UI to monitor 3D printer and control it via WiFi

- Marlin firmware settings:

#define SERIAL_PORT -1 #define SERIAL_PORT_2 2 #define BAUDRATE 250000

#define BUFSIZE 64 // optional #define RX_BUFFER_SIZE 2048 #define TX_BUFFER_SIZE 128

Precision and quality

-

- Калибровка экструдера и потока 3D принтера, Калибровка экструдера и потока. For PrusaSlicer check extrusion multiplier calibration.

- 3D printer calibration – almost the same set of steps to complete (mechanics, extruder steps, PID calibration, temperature tuning, retraction tuning, flow tuning, linear advance, …)

- Секреты качественной и стабильной 3D печати – выбор сопла и кулера hotend

- Removing Zits and Blobs on your 3D prints by merging the neighbouring segments (Print Settings → Advanced → Slicing → Resolution).

- Увеличение скорости печати: оптимизация настроек – увеличить ширину линий (например, для внутренних периметров), больше периметров вместо заполнения, увеличить высоту слоя, включить переменную плотность заполнения, использовать заполнение только для поддержек, увеличить ускорения/рывки для заполнения

Physical strength

- Comparing PLA, PETG & ASA

PETG has better UV-resistance then PLA.

PETG has better UV-resistance then PLA.

ASA has density 15% lower than PLA.

ASA has density 15% lower than PLA.

ASA has highest resistance to temperature (120°C), then comes PETG (80°C) and PLA (60°C).

ASA has highest resistance to temperature (120°C), then comes PETG (80°C) and PLA (60°C).

ASA has price per meter comparable to PETG.

ASA has price per meter comparable to PETG.

- Тест пластиков для 3D печати в салоне автомобиля 70°С+

- От менее устойчивого к более устойчивому: PLA → PETG → ABS

- The influence of layer height on the strength of FDM 3D prints, Big nozzles - how they (can) make your 3D prints stronger?Don't go beyond ½ of nozzle diameter, so for 0.4 mm nozzle use thickness use 0.1-0.2 mm layer height (so layer height is in range

[nozzle_diamater/4 .. nozzle_diamater/2]) with 0.15 is the strongest. However mind that:- Print time is inversely proportional to layer height, so smaller layer height results longer print time.

- Layer height is inversely proportional to printout weight (amount of used plastic) as the printing gets less dense, so smaller layer height results more plastic used / bigger weight.

- It is possible to emulate bigger nozzle just:

- by increasing the extrusion width which will be as fast as using a bigger nozzle, but increases load on extruder

- by adding an additional perimeter layer which will be slower than using a bigger nozzle

- "Arachne" perimeter generator added to PrusaSlicer 2.5.0 allows one to print with 0.4 mm quality using 0.6 mm nozzle in a shorter time.

- The effect of extrusion width on strength and quality of 3D printsThe strength increases when extrusion width goes up to 150% of the nozzle diameter.

- The Influence of Extrusion Temperature on Layer Adhesion, How does printing temperature affect strength?, How does the printing temperature affect strength?

- Higher temperature helps layer adhesion, so it is recommended to print at middle recommended temperature.

PETG has shown the best performance for layer adhesion at 220°C and gradually falls with temperature raise (which is different to PLA). - If you want to optimize your parts for the looks, rather go to the lower end of the recommended temperature scale. If you want to optimize your prints for strength, go to the upper limit and even a bit above (230°C for PLA and 245°C for PETG).

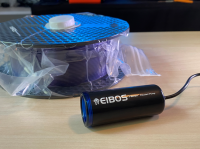

- Why you need to dry your filaments?, Vacuum vs dehydrator: what's the best way to dry filament?, Do you really need to dry your filament?, Как сушить филамент: сушилка для пластика своими руками

- Dry filament adds 20%-40% to the stiffness of your model (tested on PETG which is not so affected to hydrolysis comparing to Nylon).

- Filament is saturated in 5 days in ambient air.

- Heat drying is the most effective and fast method of filament drying. For PETG dry it for 4 hours with temperature 65°C.

- Putting a desiccant to the box bottom where the filament is stored helps to absorb the moisture.

- What is the Strongest Infill Pattern?, Testing infill patterns for their strength

- Honeycomb is the best in Y load, but most slow to be printed.

- Triangle is the optimal pattern showing the best performance with relatively same amount of printing time.

- Gyroid is unique in a sense that it shows the same maximum load in all directions.

- Increasing the infill from 15% till 30% does not have much impact on strength, so better alternative it is to use more outer perimeters where adding just one extra could technically give the same part strength as an extra 15% infill. So increase outer perimeters to 4-6 layers (which for 0.4 extrusion width will result 1.6-2.4 mm perimeter thickness).

- Gradient Infill for 3D Prints

Stiffness at the same weight is almost 30% higher with the gradient infill (is integrated to PrusaSlicer).

Stiffness at the same weight is almost 30% higher with the gradient infill (is integrated to PrusaSlicer).

General approach does not work well for all cases, e.g. small parts it might not be a great benefit or direction of the infill does not match the maximum load area.

General approach does not work well for all cases, e.g. small parts it might not be a great benefit or direction of the infill does not match the maximum load area.

- Better performing 3D prints with annealingPLA has the special property that you can increase the crystallinity in the material by cooking in pre-heated convection oven at a set temperature of 100°C for 45 minutes.

The horizontal (XY) strength was increased by about 10% (7.5%-16.2%).

The horizontal (XY) strength was increased by about 10% (7.5%-16.2%).

The model was shrunk unproportionally in different dimensions hence it is not possible to compensate that by scaling the model.

The model was shrunk unproportionally in different dimensions hence it is not possible to compensate that by scaling the model.

The vertical (Y) strength was not impacted in other words layer adhesion was not improved.

The vertical (Y) strength was not impacted in other words layer adhesion was not improved.

Is not applicable to ABS or PETG plastic which don't have such material property.

Is not applicable to ABS or PETG plastic which don't have such material property.

- Testing the strength of 3D prints re-melted in salt

This method allows to increase the layer adhesion by 150%.

This method allows to increase the layer adhesion by 150%.

A lot of post-processing effort.

A lot of post-processing effort.

- Helicoils, Threaded Insets and Embedded Nuts in 3D Prints - Strength & Strength Assessment, Threaded inserts evaluation, Threaded Inserts in 3D Prints - How strong are they?

- Threaded insert is stronger than helicoil, but probably helicoil will be cheaper (provided that you already have proper tooling).

- If you have an alternative – choose bottom pocket.

- Threaded insert is better than screwing a bolt directly into plastic.

- Stronger 3D prints with glue? – applying super glue or epoxy on the surface of the model does not add any sensitive strength to it.

- Which glues work on 3D prints? – epoxy, J-B Weld, Super Glue

Filament

- Comparing PLA, PETG & ASA – PLA sustains about 30% more load force than PETG

Models

Software and modelling

-

- Всё о настройках 3D печати. Полная инструкция по PrusaSlicer.

- You can skip 3D modeling now: Full Control GCode is a new approach to getting your 3D printer to print exactly what you want!

- Impressive 4-Axis non-planar 3D printer allows to print 90° overhangs without supports

- Achieve true 3D printing with non planar slicing allows to print 45° curved surfaces using the custom version of Slic3r.

Chocolate printing

DIY

EggBot

There are two options to build it:

Using SphereBot as a firmware:

Using Grbl with Pen Servo Feature, based on Grbl or Grbl ESP32 firmware:

Using Elekscam Software:

Using EggDuino:

Questions and answers

Minimize stringing when printing with flexible filaments

Normal operational stepper motor temperature

Extruder is skipping steps

- Убедиться, что hotend разогрет до нужной температуры и нет проблемы с забитым соплом.

- Проверить механику (прижимной механизм не сломался, прижимной механизм не сплющивает пластик, канавка прижимного ролика выровнена со шестерёнкой).

- Поднять ток на моторе экструдера (для TMC2209 это можно сделать из меню Marlin).

Parts printed with PETG get warped / bended

- Apply more glue stick to the surface (if printing on glass). Try using BF-2 glue + isoprophyle in proportion 1:2.

- Switch off part cooling fan.

- Try printing on cold bed (normally printing on 60°C-70°C bed).

- Try to decrease the nozzle temperature to 220-225°C (if normal is 230°C).

More information:

- Настройки Ender-3 для PETG пластика рекомендует, тем не менее, максимальный обдув после первых двух слоёв.

How to print with transparent plastic?

- Postprocess:

- SBS with solvent or D-Limonene

- PLA with Dichloromethane

- ABS with Acetone

- Print with big nozzle e.g. 0.8 mm so that you have less layers.

- As to Transparent FDM 3D prints the settings are: 15 mm/s speed, 0.12 mm layers, no bottom/top layers, aligned rectilinear infill (or any single directed infill), 102% extrusion flow, 220°C for PETG/PCTG (also try 30% cooling).

See:

"Девица не хочет лезть в Окно" – device not compatible with Windows.